From Bricks to Pistons: How LEGO Engines Actually Work

When most people think of LEGO, they picture colorful bricks stacked into castles, cars, or spaceships. But hidden within the world of these little plastic blocks is a fascinating side of LEGO that doesn’t just look cool — it moves. LEGO engines bring static builds to life, turning gears and pistons like miniature versions of the real machines under the hood of a car.

Whether you’ve seen a LEGO V8 engine roar to life on YouTube or tried building one yourself with Technic pieces, you’ve probably wondered: how do those bricks actually create motion? How do pistons pump, and how do gear systems power smooth rotation — all from a handful of LEGO parts?

In this post, we’ll break down the mechanics behind LEGO engines. You’ll learn how simple bricks and beams transform into moving pistons, the secret role of gears and crankshafts, and how to apply these concepts to your own custom creations. Let’s pop the hood on your imagination and explore the engine room of LEGO!

What is a LEGO Engine?

At its core, a LEGO engine is a mechanical assembly built from LEGO parts that mimics the function and motion of real-world engines. These engines aren’t just static models — they move, rotate, and pump, bringing your LEGO vehicles and creations to life. Whether powered by hand, motor, or even air pressure, LEGO engines are all about turning simple plastic parts into functional machines.

There are two main types of LEGO engines you’ll see in the wild:

Display Engines

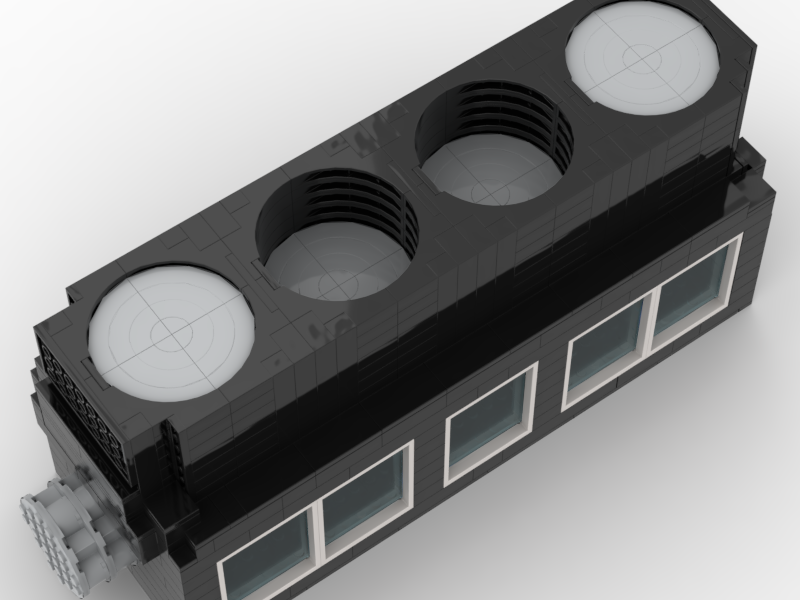

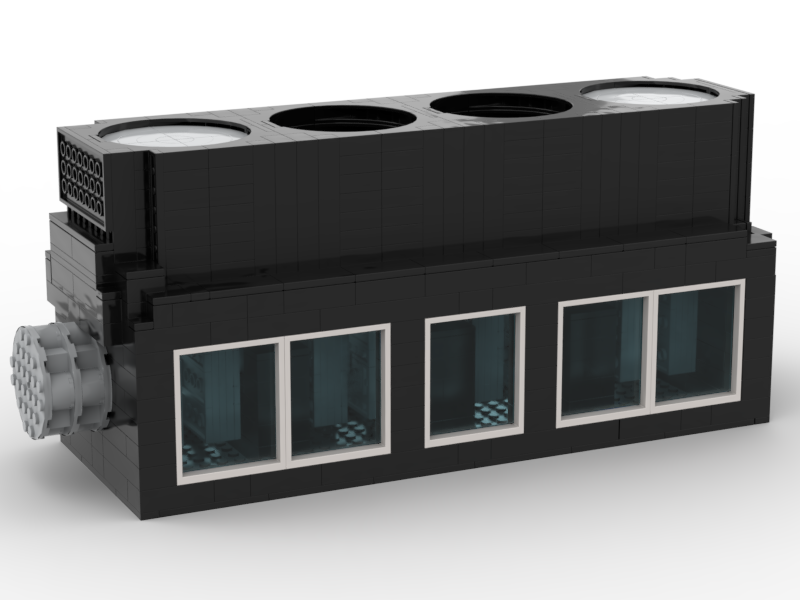

These are built mostly for looks. They feature realistic shapes, cylinder blocks, and even moving pistons, but they don’t always connect to wheels or power a vehicle. Builders create these for exhibitions or as part of larger MOCs (My Own Creations) to showcase their design and creativity.

Functional Engines

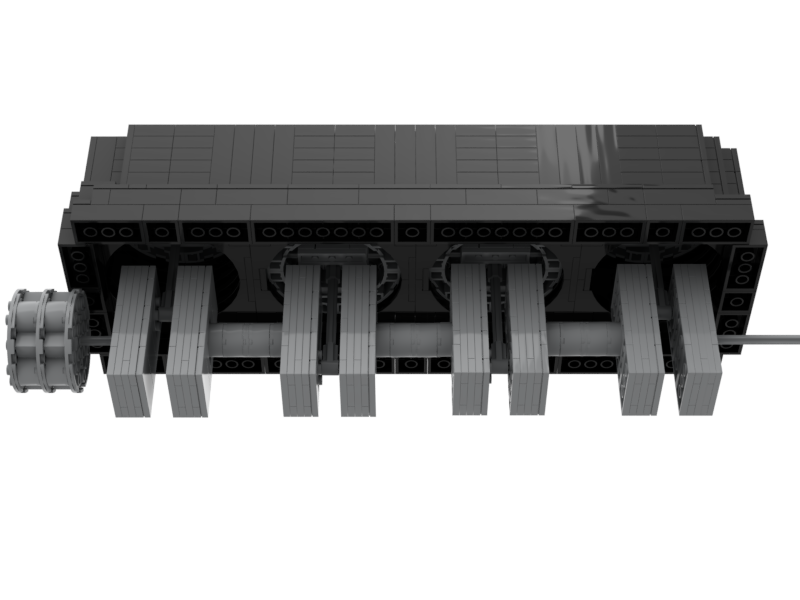

These go beyond looks. Functional LEGO engines actually produce motion, often powered by LEGO motors or hand cranks. When you rotate the crankshaft, the pistons move up and down, just like a real engine. These builds often use LEGO Technic parts like gears, axles, pistons, and crankshafts to handle the job.

Whether you’re building a V6, a V8, an inline-four, or even a flat engine, the beauty of LEGO engines lies in how real-world mechanics are scaled down to something you can snap together on your desk. The same principles that power actual cars — rotation, compression, and motion transfer — are all present, just in a playful, brick-sized format.

Ready to see how all these moving parts fit together? In the next section, we’ll break down the core components behind these clever little engines.

The Core Components

Behind every working LEGO engine is a set of carefully chosen parts. Here’s a breakdown of the core components that bring these brick-built machines to life:

- Bricks & Beams — The backbone of any LEGO build. They form the frame, engine block, and housing for moving parts.

- Axles & Bushings — Axles act like rods that spin inside the engine, while bushings secure them in place and reduce friction.

- Gears & Cogs — These transfer and adjust the speed or torque of the rotation. Gears allow small motors or hand cranks to power larger, more complex mechanisms.

- Pistons & Crankshafts — The heart of the engine. Pistons move up and down inside cylinders while the crankshaft converts that linear motion into rotational energy, or vice versa.

- Motors or Manual Inputs — Power sources that drive the engine. These could be LEGO electric motors, hand cranks, or even compressed air in advanced setups.

How Motion is Created

Now that you know the parts, let’s see how they work together to create motion:

- Power Input: A motor or hand crank supplies energy to start the rotation.

- Gear Trains: Gears adjust the speed or torque depending on the build’s needs — more torque for strength, more speed for smooth piston motion.

- Crankshaft Rotation: The crankshaft transforms the rotation into an up-and-down motion for the pistons, exactly like a real engine.

- Piston Movement: The pistons slide inside cylinders in perfect rhythm, giving the illusion of a real combustion cycle, even without fuel.

The combination of these steps creates the smooth, mesmerizing motion you see in functional LEGO engine builds. Watching it run feels like magic, but it’s all engineering under the hood!

Real-World LEGO Engine Examples

Over the years, the LEGO community has built countless mind-blowing engines, both simple and complex. Here are some standouts:

- LEGO V8 Engines: These mimic real V8 engines complete with moving pistons and crankshafts, often built from Technic pieces and sometimes paired with LEGO electric motors.

- Flathead or Boxer Engines: With pistons that move sideways rather than vertically, these builds show off another real-world engine layout in LEGO form.

- Air-Powered LEGO Engines: Using air pumps instead of electric motors, these engines can move pistons realistically with compressed air, making them a favorite in advanced Technic circles.

If you ever want inspiration, YouTube and forums like Eurobricks are goldmines for engine builds of all kinds.

Common Challenges When Building LEGO Engines

LEGO engines can be satisfying to watch, but they’re not always easy to build. Common issues include:

- Gear Slipping: If your gears aren’t secured properly, they can slip or pop under stress, especially at high speeds.

- Piston Alignment: Misaligned pistons can cause jamming or bind the entire engine.

- Friction Overload: Too much friction between parts, especially unlubricated axles and bushings, can stop the engine altogether.

- Weak Frames: Engines with poor structural support can twist and fall apart under motion, especially when paired with high-torque motors.

The key to overcoming these is patience, test-fitting, and — above all — sturdy Technic frameworks.

Advancing Your Builds

Once you’ve mastered the basics, there are many ways to push your LEGO engine skills further:

- Power Functions & Control+: Add motors, remote control, or programmable sequences to power your engines automatically.

- Gearboxes: Pair your engines with LEGO gearboxes for speed shifting, reverse, and clutch systems.

- Realism Enhancements: Cover the moving parts with engine blocks, add printed tiles for branding, or even design mock exhaust systems for that extra flair.

Combining LEGO’s mechanical precision with real-world engine principles is a gateway to advanced custom MOCs and fully functional LEGO machines.

Conclusion

LEGO engines are a brilliant blend of creativity and engineering. They teach real mechanical principles — like motion transfer, rotational energy, and synchronization — while staying fun and hands-on. Whether you’re building a display model or a fully functional piston engine, every piece clicks together in a way that deepens your understanding of machines.

So the next time you snap a Technic beam onto an axle, think beyond the brick. With a little imagination and the right parts, your LEGO engines can roar to life — no fuel required.

If you want to see some of my designs please click here